Cartridge heaters play an important role in industrial manufacturing processing. Cartridge heater is small size, however could have large power and provides stable heat source. It is a very good choice for industrial production processes that require efficient and fast heating.

Reheatek cartridge heaters have two different series, they are common cartridge heaters and uniform cartridge heaters with different heating effect. Common cartridge heaters can be applied to most application scenarios, such as plate heating, preheating machinery, and molds etc.. Uniform cartridge heaters are specially designed for application scenarios that require high temperature uniformity, such as a constant temperature operating table for noble metal processing, packaging sealing machine, and a high-precision melt-blown Machine mould etc.

Uniform cartridge heater provides uniform temperature output in the heating part. Then the question arises-how does Reheatek make the temperature output uniform?

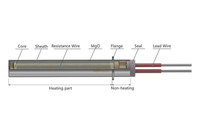

To illustrate this, we should first understand the construction of cartridge heater:

The reason why cartridge heaters can generate heat is that the core is a heating wire made of nickel-chromium alloy. The heat generated at both ends of the heating wire is transferred to the metal shell through the insulated magnesium oxide powder, and the heated object comes into contact with the shell and absorb heat to complete the heat conversion process.

Common cartridge heaters heating wires are evenly wounded . This method is less difficult to process, and can be applied to most heating scenarios. Due to the larger heat dissipation area at both ends, the heat dissipation speed is faster than the middle, so from the perspective of heat distribution, the temperature in the middle will be slightly higher than the temperature at both ends:

Although the common cartridge heaters has a wide range of application, it is slightly insufficient when facing more elaborate application scenarios. High-precision machinery or molds have strict temperature requirements, not only the accuracy of temperature control, but also the uniform temperature of each part.

The above scenarios have very high requirements on the temperature uniformity of the cartridge heaters. Uneven temperature will affect the quality of the product being produced. It is necessary to select Reheatek uniform cartridge heaters.

Uniform cartridge heater takes the application environment into consideration. After calculation and simulation, a suitable power distribution is customized, and the heating wire winding density is adjusted according to this power distribution:

From the above figure we can see that when the heating wire is wound, the density of the two ends and the middle part is not uniform. The higher the density of the two ends, the greater the power of two ends is. Heat dissipation of two ends is faster than the middle, which generates uniformly distributed heat source.

The whole heating part of uniform cartridge heater transfer almost the same temperature, the heated object can be heated up uniformly and stably to achieve more perfect working conditions, it’s more efficiency and reduce energy loss. Especially in the application of precision molds, the uniform cartridge heater effectively solves the problem of uneven temperature of the mold and guarantee more elaborate products.

Uniform cartridge heater achieves a stable and uniform heating effect by arranging heating wire winding density without damages. This structure has passed the performance test and life test in Reheatek professional laboratory . Many customers repurchased with good feedback.

Suzhou Reheatek will continue to provide customers with more efficient and energy-saving products!