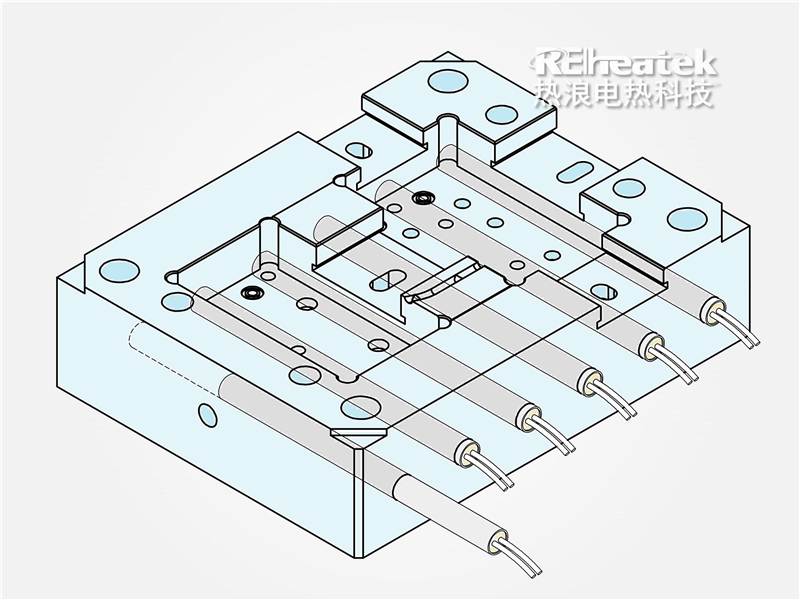

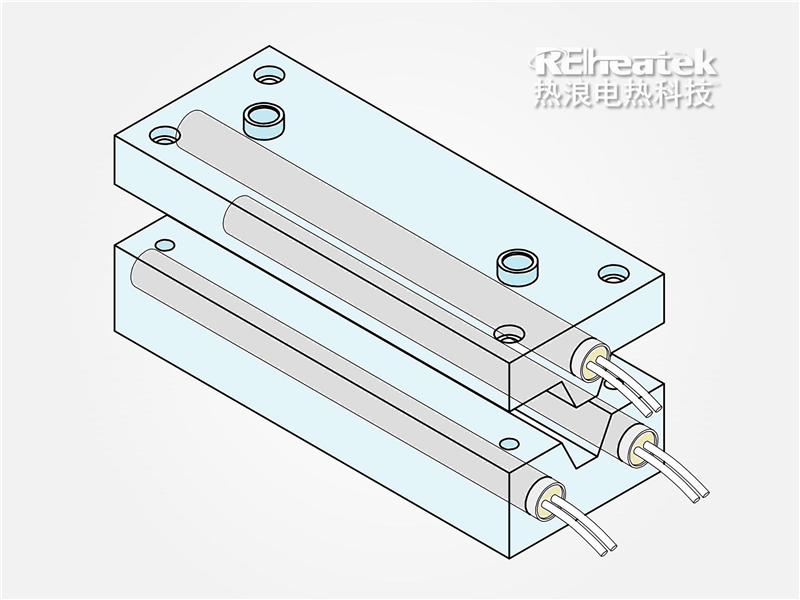

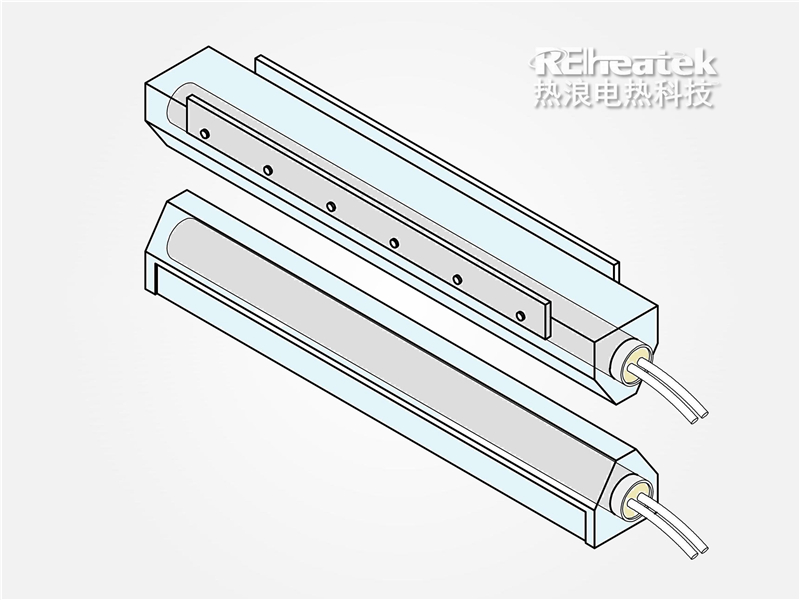

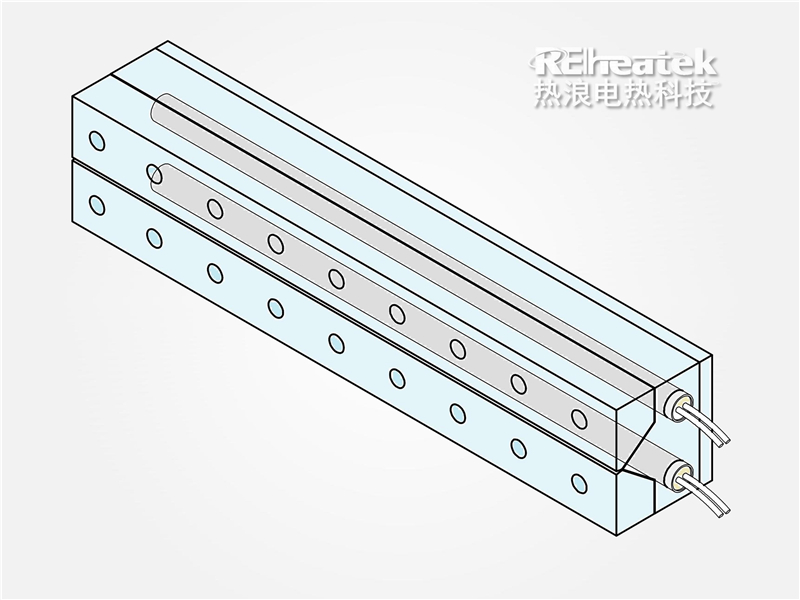

Metal Molds

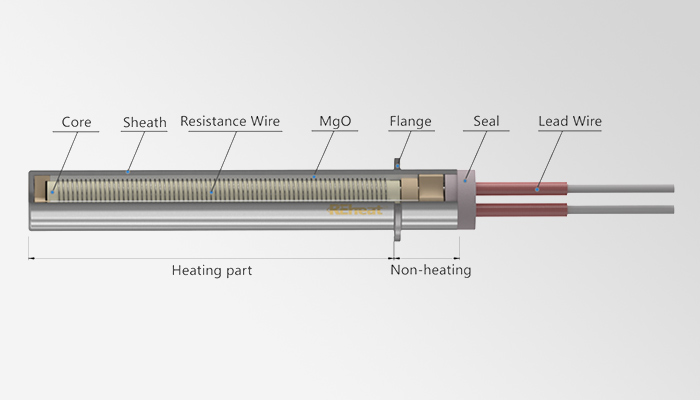

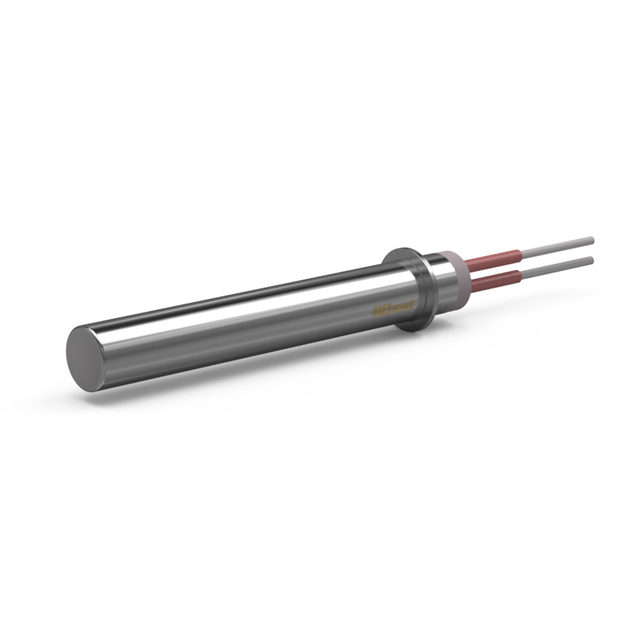

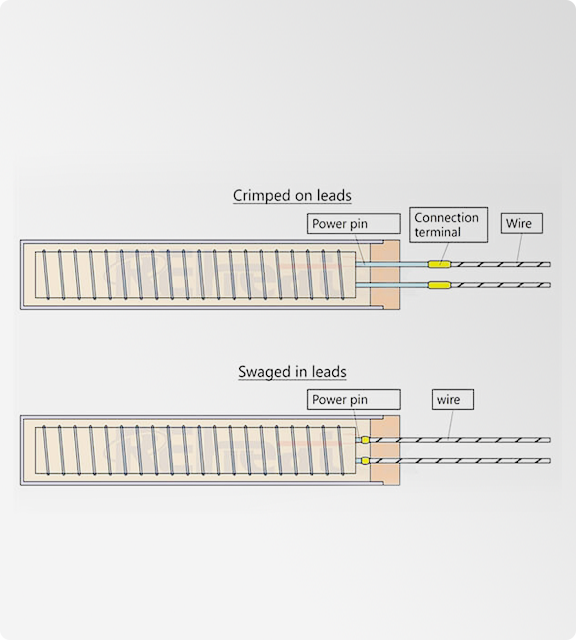

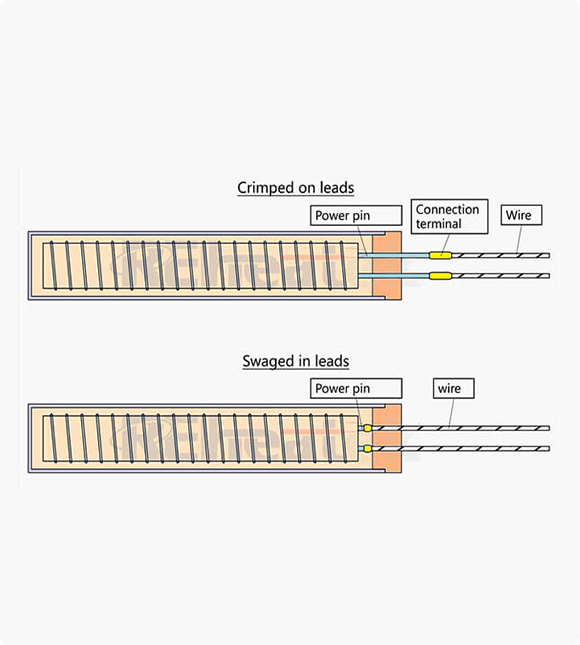

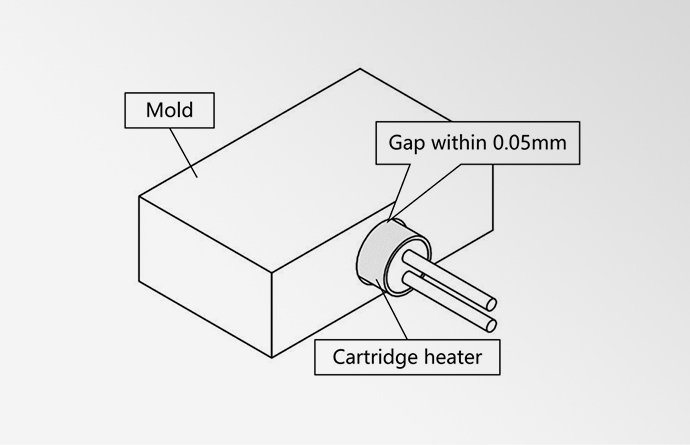

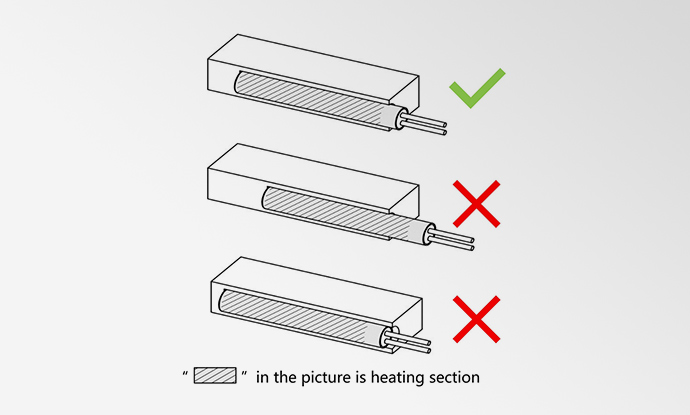

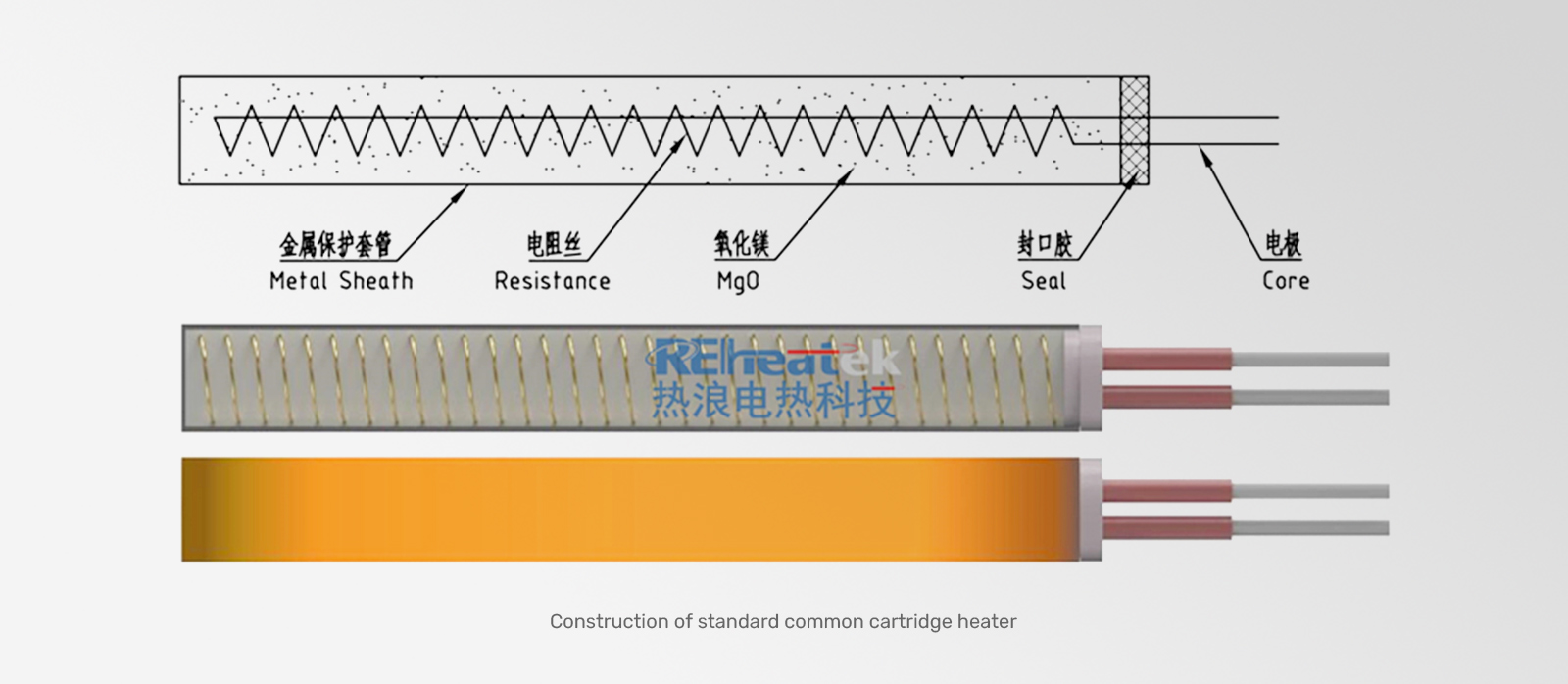

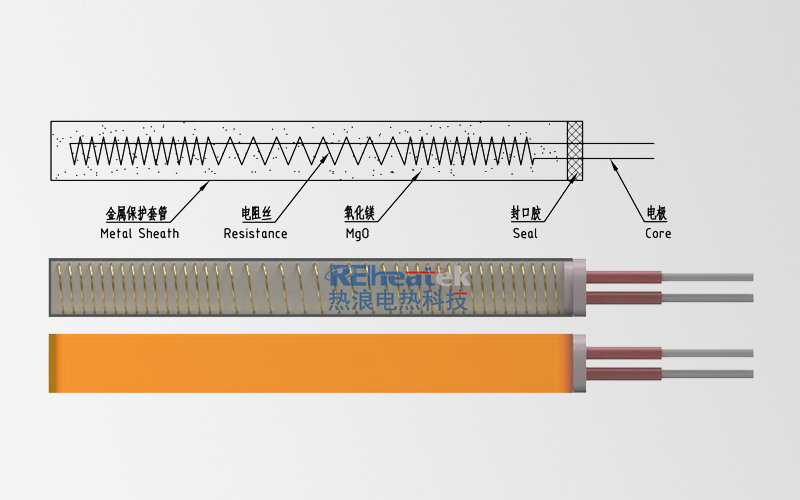

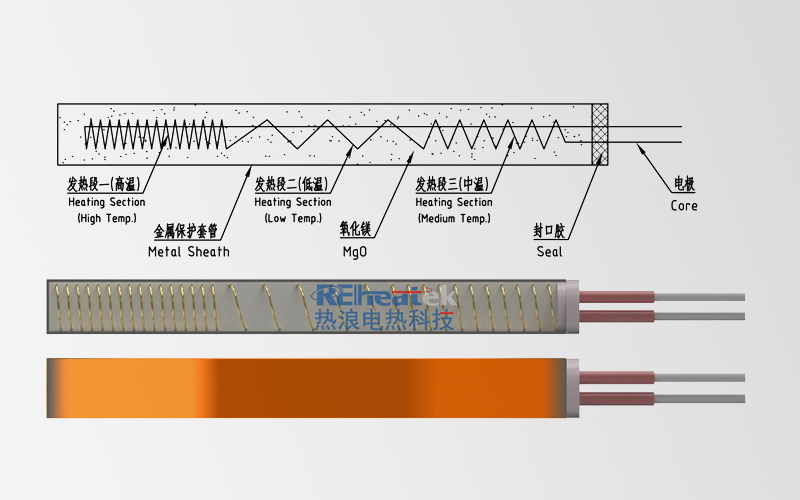

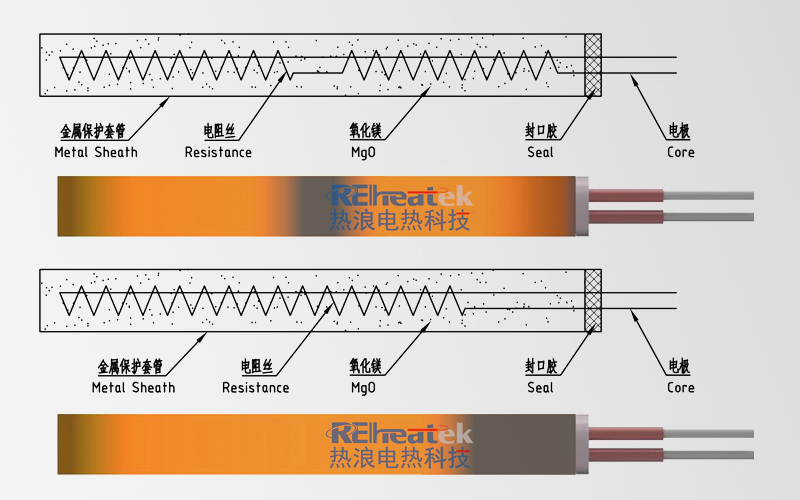

Cartridge heaters provide precise and efficient heating for die casting, injection molding and other metal forming tooling applications. The tube design allows it for quick and easy installation.

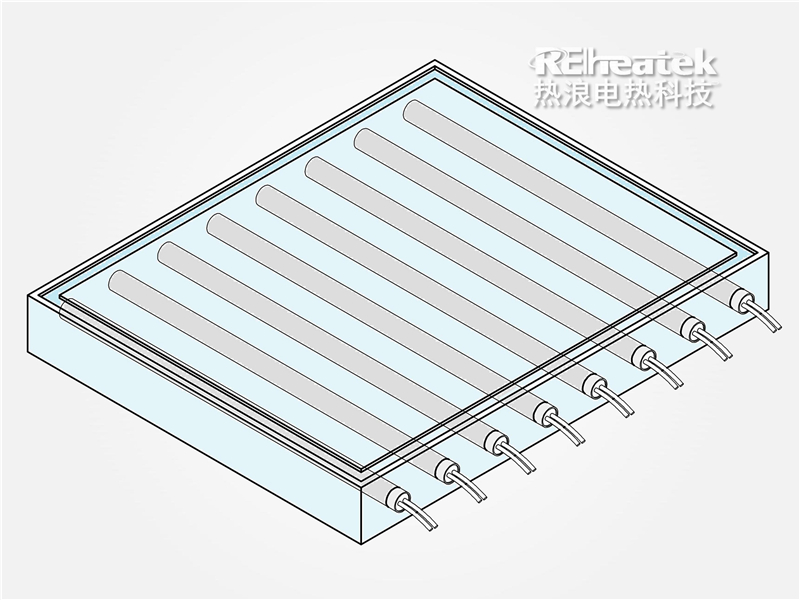

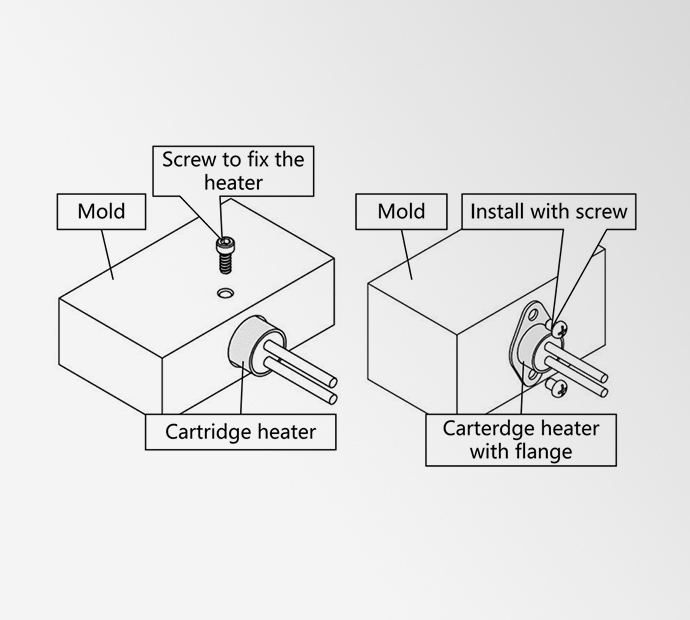

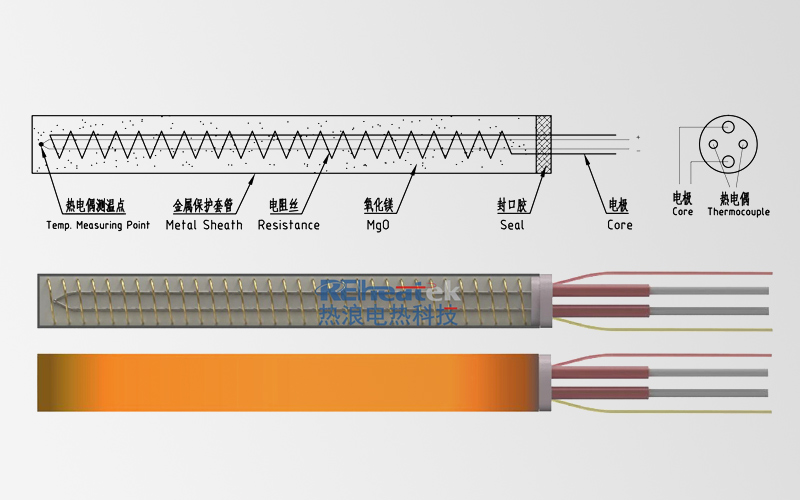

Aluminum Heating Platform

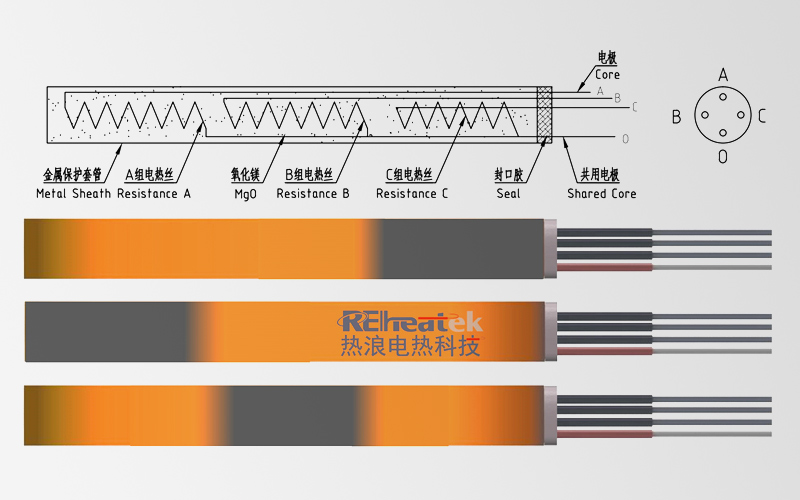

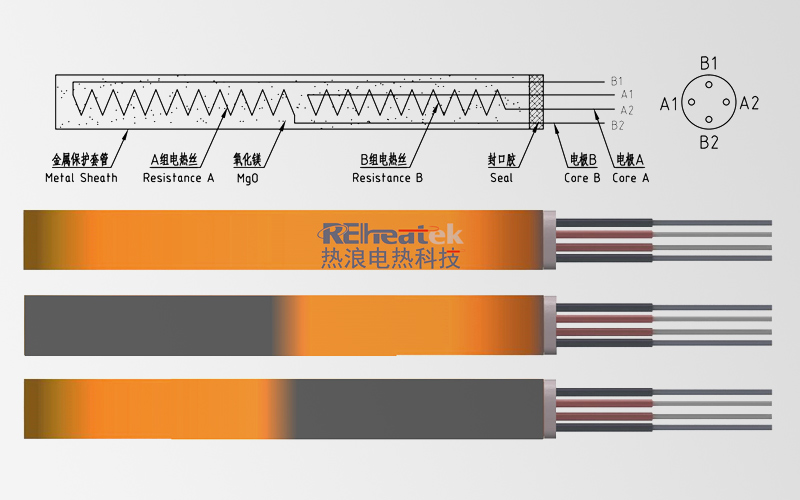

Cartridge heaters and thermouples are integrated to the platform to deliver precise temperature control for optimal heat management.